The Ultimate Guide To Freeze Dryer

Wiki Article

The Only Guide for Cooler

Table of ContentsIndicators on Direct Cooling Freezer You Should KnowFreezer Fundamentals ExplainedUnknown Facts About Freezer FreonAll About Cooler

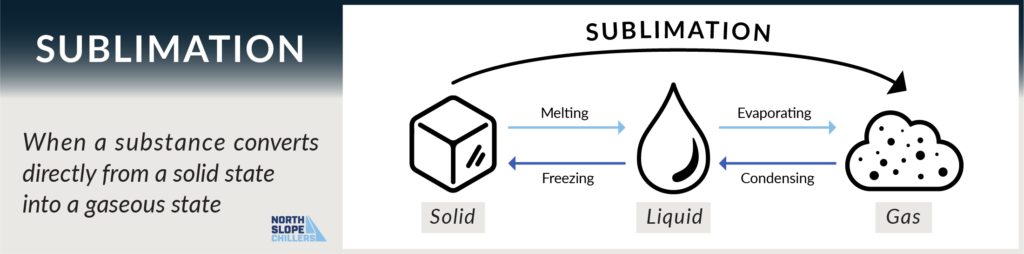

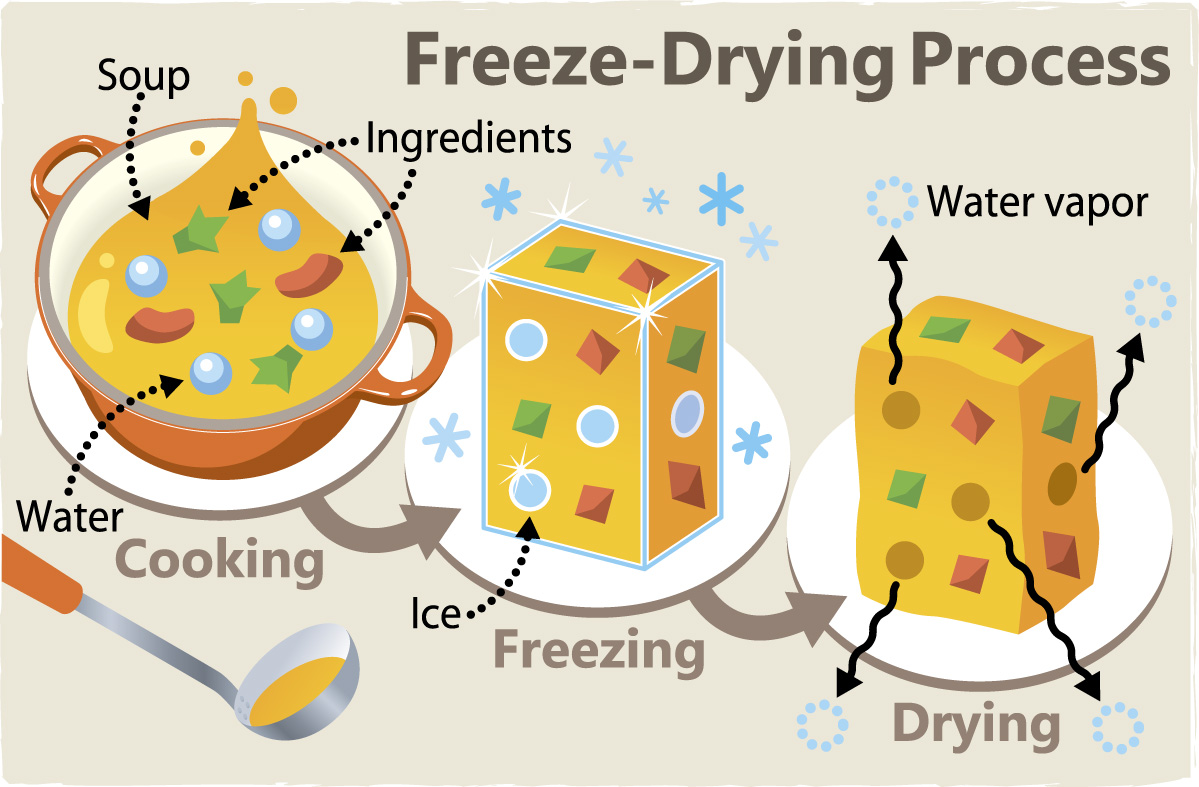

Suspended animation or lyophilization is a dehydration method based on the sublimation of water in an item (, ). This means that the item's water material shifts from a strong to a gaseous state or from ice to vapor without going via the fluid state (). Freeze-drying is considered a premium quality dehydration technique for a number of reasons, consisting of (, ): it runs at low temperature levels, which adds to preserving a product's nutritional worth, preference, look, as well as heat-sensitive compoundsfreezing hinders chemical as well as microbiological processes, which significantly postpones the product's damage (thereby expanding its rack life) Raw foods are consisted of about 80%95% water, which can be separated right into "free" and also "bound" water.In the freeze-drying process, all cost-free water as well as some bound water needs to be eliminated, and also cost-free water has to remain frozen whatsoever times. This is the key distinction between freeze- and also vacuum-drying and the most difficult action (). The freeze-drying procedure can be divided right into 3 actions (,, ): The product is often frozen under climatic pressure.

Recognized as desorption drying out, it's the drying out of products to their preferred moisture by getting rid of the remaining bound water - deep freeze unfreezer. Freeze-drying ought to be carried out in controlled conditions that do not thaw the water, seeing that the existence of liquid water may transform the item's composition, form, and also physical homes ().

Freeze drying out happens in three phases: Freezing Main Drying (Sublimation) Second Drying (Adsorption) Appropriate freeze drying can minimize drying times by 30% Cold is the most crucial stage of freeze drying, as well as there are many methods for it. Cold can be performed in a fridge freezer, a cooled bath (covering freezer) or on a shelf in the freeze dryer (cooler).

The Ultimate Guide To Freeze Dryer For Home

Freeze drying is easiest to achieve using huge ice crystals, which can be produced by sluggish cold or annealing. With organic materials, when crystals are too large they may damage the cell wall surfaces, and also that leads to less-than-ideal freeze drying out results.

About 95% of the water in the material is removed in this stage. Primary drying can be a slow-moving procedure. Way too much warm can change the structure of the product. Freeze drying's final phase is additional drying out (adsorption), throughout which the click here for more ionically-bound water particles are eliminated. By elevating the temperature level higher than in the primary drying out stage, the bonds are broken between the material and the water particles.

After the freeze drying process is full, the vacuum cleaner can be braked with an inert gas before the product is secured. Many materials can be dried out to 1-5% residual wetness.

Indicators on Direct Cooling Freezer You Need To Know

The essential principle in freeze-drying is sublimation, the change from a solid straight into a gas. Just like evaporation, sublimation occurs when a molecule gains enough energy to damage without the molecules around it. Water will superb from a solid (ice) to a gas (vapor) when the particles have enough power to damage complimentary yet the problems aren't right for a liquid to form (direct cooling freezer).For a substance to take any type of particular phase, the temperature level and pressure have to be within a certain range. The chart listed below important source shows the required stress as well as temperature values of various stages of water.

06 atmospheres (ATM), the water is cozy enough to thaw, however there isn't sufficient pressure for a fluid to develop. It ends up being a gas. This is exactly what a freeze-drying device does. A normal device is composed of a freeze-drying chamber with a number of shelves connected to heating devices, a cold coil connected to a refrigerator compressor, and an air pump.

When you seal the chamber and begin the procedure, the maker runs the compressors to decrease the temperature level in the chamber. The material is iced up strong, which divides the water from whatever around it, on a molecular level, despite the fact that the water is still present. Next off, the machine activates the air pump to require air out of the chamber, reducing the climatic pressure below.

Our Cooler Statements

Given that the stress is so low, the ice turns directly into water vapor. The water vapor condenses onto the freezing coil in strong ice form, in the exact same way water condenses as frost on a chilly day.

This allows food to come to be shelf-stable for 20-25 years. Yes, they are undoubtedly amongst the more expensive food preservation approaches. Have a look at this message if you're searching for my fave. It is necessary to know that freeze drying is different than dehydrating. Read this article if you're unclear of.

A few days ago a buddy asked me if I'm as delighted about it as I was when I initially got it. Well, I'm a lot more thrilled really, and also after that conversation, I went out and purchased a second unit! To be honest, I had not been extremely ecstatic concerning the freeze dryer at.

Report this wiki page